SEVERNE BLADE 2023

1030.00 CAD$ – 1236.00 CAD$

Description

The Blade has defined the 5-batten wave sail category for nearly two decades.

With the new GRADIENT PANEL TECHNOLOGY improvements are obvious. Lighter weight and better stability.

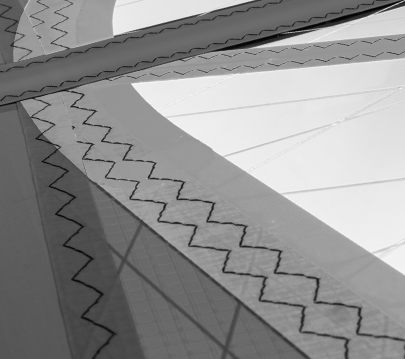

Corners have overlapped panels which reduces the amount of patching. At the same time, these overlapped areas extend into the body of the sail so it transitions the load much better, will be less stretched over time. It’s a more stable way of building sails.

Rather than a single curved luff panel, the Blade uses separate panels that radiate out of the head and tack corners. This perfectly aligns the sail material with the direction of load. Previously the curved panel would have bias stretch in all the wrong places. Direct transmission of power. Increased longevity. Total Control.

FEATURES

- I00% XPLY

- DOUBLE SEAMS EVERYWHERE.

- BENCHMARK WAVE SAIL

2023 UPGRADES

- GRADIENT PANEL TECHNOLOGY

- MORE STABLE

- LESS STRETCH

- LIGHTER

SPECS

| Blade | Luff | Boom | Battens | Weight | Head | Recommended Mast | Enigma Boom | Boom | Extension | |

|---|---|---|---|---|---|---|---|---|---|---|

| 3,0 | 344 | 140 | 5 | 2,18 | ADJ 11CM | SEVERNE 340 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 24 |

| 3,3 | 341 | 141 | 5 | 2,16 | FIXED | SEVERNE 340 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 24 |

| 3,5 | 352 | 146 | 5 | 2,24 | FIXED | SEVERNE 340 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 24 |

| 3,7 | 369 | 148 | 5 | 2,34 | FIXED | SEVERNE 340 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 36 |

| 4,0 | 379 | 150 | 5 | 2,42 | FIXED | SEVERNE 370 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 24 |

| 4,2 | 385 | 154 | 5 | 2,49 | FIXED | SEVERNE 370 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 24 |

| 4,5 | 404 | 157 | 5 | 2,64 | FIXED | SEVERNE 370 Wave | RDM | Enigma 140 | METAL 140 | Cyclops 36 |

| 4,7 | 406 | 160 | 5 | 2,68 | FIXED | SEVERNE 400 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 24 |

| 5,0 | 414 | 164 | 5 | 2,78 | FIXED | SEVERNE 400 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 24 |

| 5,3 | 423 | 168 | 5 | 2,86 | FIXED | SEVERNE 400 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 24 |

| 5,5 | 429 | 170 | 5 | 2,95 | FIXED | SEVERNE 400 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 36 |

| 5,7 | 433 | 171 | 5 | 3,02 | FIXED | SEVERNE 430 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 24 |

| 6,2 | 455 | 174 | 5 | 3,18 | FIXED | SEVERNE 430 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 36 |

| 6,7 | 462 | 183 | 5 | 3,31 | FIXED | SEVERNE 460 Wave | RDM | Enigma 150 | METAL 150 | Cyclops 24 |

TECHNOLOGY

SEAMLESS HEAD PANEL This high abrasion area is made from only 1 panel and does not carry any exposed seams, preventing any potential weak point in this area. As a result, seam creep and seam-related failure have been eliminated.

SEAMLESS FOOT CONSTRUCTION A single panel in the foot area with hidden load patches and zero exposed stitching eliminates seam abrasion and seam creep in this high load area. Maximum durability and minimum weight.

3&4 ROLLER TACK PULLEY Roller tack pulleys are matched to the sails downhaul requirements and aligned for friction free downhauling and threading ease. Rig your sails with the Severne Hardware Division extensions for function and simplicity.

|

VX2 / MATERIAL / ADVANTAGES. MORE STABLE. |

DOUBLE SEAMS All Severne wave sails have 25mm double stitched window seams. The wider, single colour seam tape ensures maximum tear strength and crash resistance  MOLDED SOFT EDGE With recessed grooving, covering any vulnerable stitching the moulded soft edge encloses the hard edge long the foot of the sail and protects the stitching from wear along the board non-skid.

| BOOM HEIGHT REFERENCE Boom height gauge for ease of reference.  SPIDERFIBRE A web of fibreglass filament that disburses loads across seams and throughout the body of the sail. By using stronger, lighter fibres and reducing sail patching, we can measurably reduce weight and swing weigh and at the same time, increase strength.  EM4 HIGH LOAD LAMINATE Based on the proven eM3 platform, the high load eM4 material features twice the amount of X-Ply fibre and increased film thickness to maximise durability. This new material allows weight reduction whilst maintaining puncture resistance and tear strength. Used in the lower impact zone in the sail.

|

THERMOFORMED TACK FAIRING Protects your board from impact and neatly covers the foot detailing. It incorporates the rope stash pocket for easy storage of your downhaul rope. |

Content missing